Control System For A Window Spacer Bending Machine

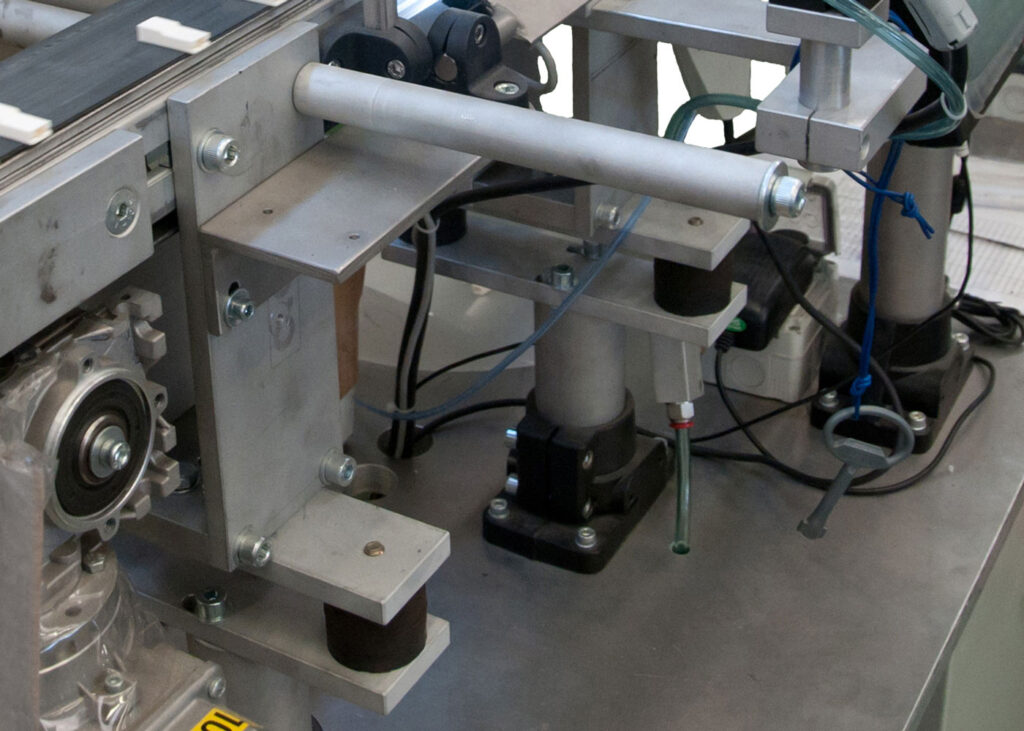

A custom machine builder needed to upgrade its existing control system for a machine that manufactures the metal spacers that separate the panes of glass in a window. Mercator Automation designed and manufactured the system of electrical and software elements that allowed the metalworking machine to:

A custom machine builder needed to upgrade its existing control system for a machine that manufactures the metal spacers that separate the panes of glass in a window. Mercator Automation designed and manufactured the system of electrical and software elements that allowed the metalworking machine to:

- Bend a straight piece of aluminum extrusion into the shape of a rectangle;

- Saw the material to the correct length;

- Drill a series of holes automatically.

We were successful delivering a control system upgrade that could meet these requirements to a tolerance of 1/32″.

Mercator Automation’s PC-based HMI for this project included a SQL database (for storing batch jobs, material parameters, machine parameters, and alarm history) and several custom screens built with Visual Basic for machine setup and monitoring. We developed motion control and machine sequencing software for a 3-Axis Baldor servo controller. We also redesigned and rebuilt the control panel, and rewired all sensors and solenoid valves on the machine. Extensive testing ensured that our work would continue to meet the rigorous standards for accuracy held in the tool-and-die industry.

To learn more about this project, or our other products and services, please contact Mercator Automation.

Control System Upgrade of Window Spacer Bender Machines – Project Details

| Product Description | Mercator Automation designed and manufactured a control system upgrade for a window spacer bending machine. The scope of work included programming a PC based HMI, writing motion control and machine sequencing software, redesigning and rebuilding the control panel and rewiring all the sensors and solenoid valves on the machine. |

| Capabilities Applied/Processes | Machine Control

HMI

Control Panel

|

| System Features & Specifications | This machine automatically builds the metal spacers that are placed between the panes of glass in a window. The machine takes straight pieces of extruded aluminum stock and bends them into a rectangle. The material is automatically cut to length with a saw and a series of holes are drilled. The overall dimensions of the rectangle have a tolerance of 1/32″. |

| In process testing performed | Rigorous functional testing of the HMI and machine control software was performed in our facility prior to delivery of the upgraded machine. Extensive testing of machine accuracy was also completed. |

| Industry for Use | Custom Machinery |

| Delivery Time | 6 to 8 weeks |

| Standards Met | Customer supplied specifications |

| Product Name | Control System Upgrade of Window Spacer Bending Machines |